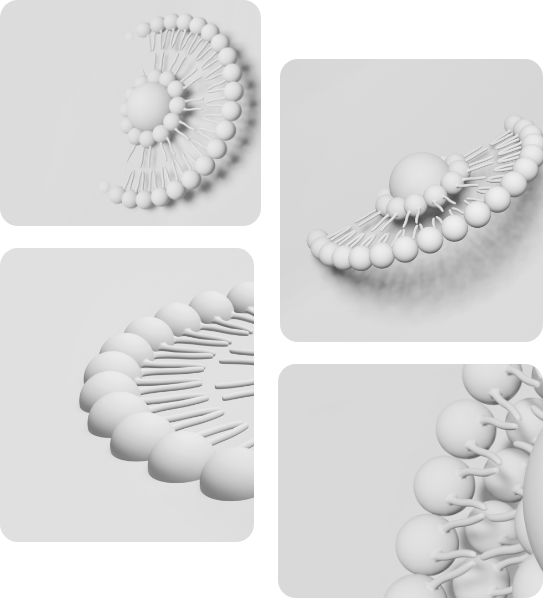

Let's collaborate and create quality liposome encapsulated drugs together. Contact Us!

At SyVento BioTech, we understand the critical importance of the final step in drug product manufacturing. That is why we aim to provide excellent fill and finish services in our soon-to-open, state-of-the-art facility designed to meet cGMP standards and ensure consistent product quality and control.

Process Scaling

We offer the possibility of scaling the production of formulations based on lipid nanocarriers by transferring solutions developed in the laboratory on a semi-technical and technical scale. Thanks to the extensive equipment base, we are able to perform:

starting from very small batches (25µl) and up to 50L batches:

Our production line is capable of continuously filling 2000-3000 vials per hour, ensuring efficient and seamless fill and finish operations

We utilize advanced technologies, such as isolators, lyophilizers, and automated filling equipment, to ensure high product quality and safety. Our services include formulation development, analytical services, and manufacturing process development. We provide customizable solutions to meet the specific needs of each Partner while ensuring quality control and regulatory compliance.